Multiscale Kinetic Modeling of Hydrides

Category

Modeling/Simulation

Laboratory

Lawrence Livermore National Laboratory (LLNL) and Sandia National Laboratories (SNL)

Capability Experts

Tae Wook Heo ([email protected]), Xiaowang Zhou ([email protected]), Patrick Shea ([email protected]), Tadashi Ogitsu ([email protected]), Keith Ray ([email protected]), Rongpei Shi ([email protected]), Brandon Wood ([email protected])

Description

Performance and reversibility of metal hydrides are largely determined by the combined kinetics of chemical reactions, mass transport, phase transformations, and the associated microstructure evolution during cycling. The relevant chemical, physical, and materials processes occur at multiple length and time scales. The modeling and simulation capabilities within HyMARC provide foundational understanding of these operating kinetic mechanisms, which can help to identify rate-limiting processes of (de/re)hydrogenation. In particular, the kinetic modeling capabilities of HyMARC include:

- Mesoscale modeling of (de)hydrogenation kinetics

- Microkinetic modeling of kinetic processes

- Mass transport modeling.

Mesoscale modeling of (de)hydrogenation kinetics: HyMARC simulations of full (de)hydrogenation kinetics in metal hydrides are based on the integrated phase-field method [1], parameterized by thermodynamic and kinetic properties that are derived from a combination of atomistic calculations or experiments. This technique is quite general and applicable to various classes of hydrogen storage materials ranging from simple interstitial hydrides to complex metal hydrides.

Microkinetic modeling of kinetic processes: Microkinetic models are designed for exploring kinetic phenomena involving multiple coupled mechanisms, such as surface dissociation, diffusion, and adsorption of hydrogen. This technique can be used to verify the impacts of individual operating mechanisms on the overall (de)hydrogenation kinetics [2].

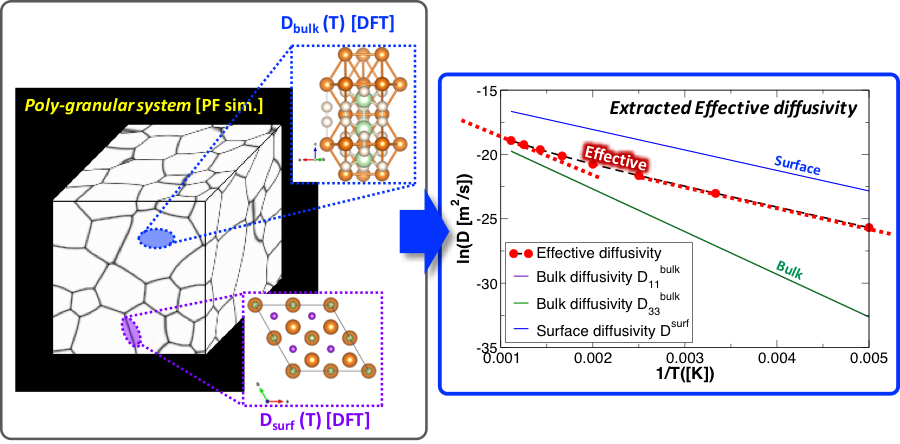

Mass transport modeling: HyMARC employs both atomistic (classical and ab initio molecular dynamics) and mesoscale simulation techniques to understand and predict mass transport of hydrogen and other species in metal hydrides. The atomistic modeling techniques aid understanding of transport pathways and mechanisms for development of improvement strategies, while simultaneously providing necessary kinetic parameters for the mesoscale modeling. Our mesoscopic mass transport models can additionally explore the effects of microstructural features within complex microstructures containing multiple grains, phases, and their boundaries.

Figures

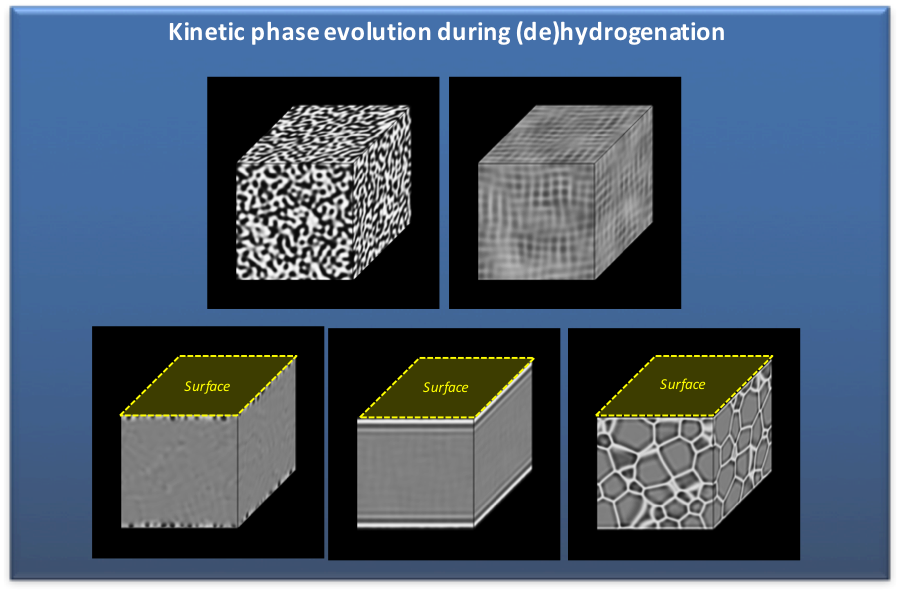

Examples of microstructures predicted to evolve within a model interstitial hydride based on phase-field simulations parameterized by atomistic calculations. The microstructure depends on various factors, including the (de)hydrogenation conditions and the presence of aligned surfaces (bottom panels).

Scheme for multiscale modeling of mass transport during (de)hydrogenation of a polycrystalline hydride based on atomistic descriptions of bulk and grain boundary diffusion.

References

- T. W. Heo and L.-Q. Chen, “Phase-field modeling of displacive phase transformations in elastically anisotropic and inhomogeneous polycrystals,” Acta Mater. 76 (2014): 68.

- K. G. Ray, L. E. Klebanoff, J. R. I. Lee, V. Stavila, T. W. Heo, P. Shea, A. A. Baker, S. Kang, M. Bagge-Hansen, Y.-S. Liu, J. L. White and B. C. Wood, “Elucidating the mechanisms of MgB2 initial hydrogenation via a combined experiment-theory study,” Phys. Chem. Chem. Phys. 19 (2017): 22646.

- E. S. Cho, A. M. Ruminski, Y.-S. Liu, P. T. Shea, S. Kang, E. W. Zaia, J. Y. Park, Y.-D. Chuang, X. Zhou, T. W. Heo, J. Guo, B. C. Wood, and J. J. Urban, “Hierarchically controlled inside-out doping of Mg nanocomposites for moderate temperature hydrogen storage,” Adv. Funct. Mater. 27 (2017): 1704316.