Computational Characterization and Screening of Porous Sorbents

Category

Modeling/Simulation

Description

Hybrid high-throughput molecular simulation and material informatics approaches have been developed to provide capabilities to efficiently characterize and screen porous sorbents of various classes. In particular, the Zeo++ code1 was developed by Haranczyk and enables one to efficiently characterize and compare a variety of porous structures from crystalline zeolites and metal-organic frameworks (MOFs) to amorphous species. The Zeo++ algorithms allow rapid calculation of restricting pore diameters (with accuracy below 0.02 Å), pore size distributions, and accessible pore volume and surface area with respect to particular guests. They can also quickly analyze materials to detect specific binding sites, such as open metal sites in MOFs. The Haranczyk group is also codeveloping porous material datasets, which allow rapid identification of structures with both desired chemistry and porosity, as well as high-throughput screening using Grand Canonical Monte Carlo simulations to predict adsorption properties. In particular, the Computation-Ready, Experimental (CoRE) MOF database2 contains more than 4,700 porous MOF structures that have been curated to remove solvent molecules and partially occupied or disordered atoms. The above developments are used within HyMARC to screen all synthesized MOFs to identify representative structures to identify those that are worthy of full experimental investigation within the hydrogen storage context. These computational tools are also being used to implement within HyMARC the Materials Genome approach, which will computationally assess hydrogen storage performance of known MOFs.

Status

Currently available for use in collaboration with HyMARC.

Figures

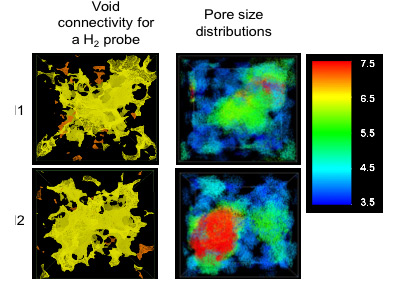

Analysis of dynamic changes to porosity in an amorphous porous material. Two rows correspond to selected two snapshots of a molecular simulation of the system. The left column presents void space inside the material accessible to hydrogen color-coded by accessibility (yellow correspond to channel systems, orange corresponds to probe-inaccessible void spaces). The right column presents visualization of pore size distribution (color coded by pore diameter). The corresponding calculations are performed within Zeo++ software.

References

- F. Willems, C. H. Rycroft, M. Kazi, J. C. Meza, and M. Haranczyk, “Algorithms and tools for high-throughput geometry-based analysis of crystalline porous materials,” Microporous and Mesoporous Materials 149 (2012): 134–141.

- Y. Chung, J. Camp, M. Haranczyk, B. Sikora, W. Bury, V. Krungleviciute, T. Yildirim, O. Farha, D. Sholl, and R. Snurr, Chemistry of Materials 26 (2014): 6185–6192.